Equipment

The integrated Flying Bridge (IFB) incorporates a design that combines the motion control, pump and high-pressure components of a waterjet cutting tool into one compact machine. It consumes minimal floor space, provides excellent operator access, and is configured for easy material loading and unloading. This abrasive waterjet machine is capable of cutting any metal, stone, tile, and glass material with unmatched accuracy and intricacy.

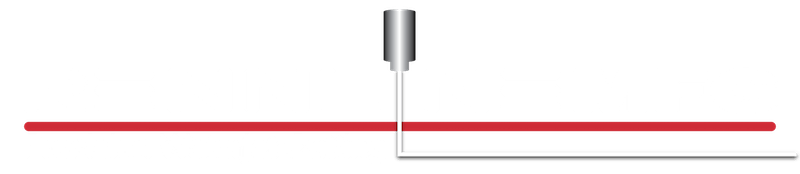

Water Jet

2012 Flow Dynamic Mach3 Flying Bridge

- 5’X10’X5.875″ Cutting Envelope

- 94,000 PSI

- Ultra Pierce (ideal for composites and laminates) and contour follower

Tolerances up to +/- .002

Water Jet

2006 Flow Dynamic Flying Bridge

- 4’X8′ X 5.875″ Cutting Envelope

- 60,000 PSI

- Ultra Pierce – ideal for composites and laminates. and contour follower

- Tolerances up to +/- .002

CNC Machining Center

2012 Hurco VM10

- Work cube of 26″x16″x20″

- 15 hp spindle motor

- High speed 10,000 RPM spindle

- 20 station automatic tool changer

Position Tolerance: ±0.0002

Repeatability Tolerance: ±0.0001

CNC Lathe

2007 Haas SL20

8″ Chuck

- 10″ Turning Diameter

- 20 HP Motor

- Chip Auger

- Tailstock

- Parts Cache

Press Brake

2007 Accurpress Model 7608

60 ton 8′ CNC back stop

Press brake – 1969 Verson Model CS-105

45 ton 6′

4 post press – Beckwood Model 1001486 100 ton

2’x7′ bed

H-press – Enerpac 45 ton

Slip Rolls – Tennsmith 36″

Finger Brake – Tennsmith 48″

Finger Brake – DI -ACRO 12″

Shear – Tennsmith 48″

Bead rollers, shrinkers and stretchers

Wide Belt Sander

Timesaver 137

36″ wet or dry

Belt Sander – Radius Master

Belt Sander – Burr King Model 760

Belt Sander – 6″ x 72″ – Floor unit

Tumbler – Burr King Vibratory Model 45

36″ X16″ X16″

Sandblasting – Trinco 40″ X40″ with reclamation system

Buffer – Balder floor unit

Multiple hand sanders and buffers

Cold Saw

Scotchman 12″ Pneumatic Jaws

Band Saw – Jet 20″

Chop Saw – Hitachi 14″

Table Saw – PowerMatic

Tig Welder

Lincoln Square Wave 275

Mig – (2) Lincoln 255

Spot – Chicago

Stud – Midwest CD-100

Additional Equipment

- Spray Booth – Side Draft

- Vinyl Plotter – 24″ for paint mask, vinyl graphics and mask.

- Screen Printing – We have a full screen shop with capabilities to print on most materials other than textiles.